Services

Laser Engraving Services: Precision Meets Personalization

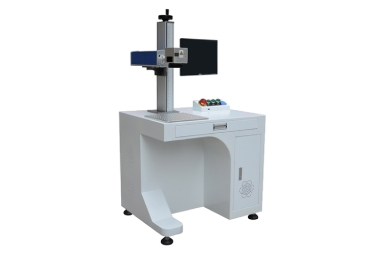

Fiber Laser Engraving (30W)

Diode Laser Engraving (40W)

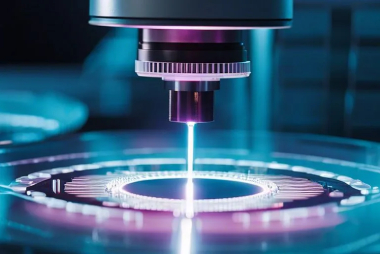

Laser engraving is a cutting-edge technology that uses concentrated light to engrave designs, text, or patterns onto a wide variety of materials. This process ensures high precision, durability, and customization, making it ideal for personal and professional applications.

Why Choose Laser Engraving?

Laser engraving is a cutting-edge technology that uses concentrated light to engrave designs, text, or patterns onto a wide variety of materials. This process ensures high precision, durability, and customization, making it ideal for personal and professional applications.

Durability:

Engravings are permanent and resistant to wear, ensuring your designs last for years without fading or chipping.

Versatility:

Laser engraving works on a variety of materials,including:Stainles Steel,Aluminium,Copper,Metal,Wood,Acrylic,Glass,Leather,Plastics.

Eco-Friendly Process

Unlike traditional engraving methods, laser engraving minimizes waste and uses no harsh chemicals, making it an environmentally friendly option.

Applications of Laser Engraving

Laser engraving is widely used across industries and for personal projects

- Corporate Branding: Engrave logos, names, or designs on promotional items such as pens, keychains, or drinkware.

- Personal Gifts: Add a personalized touch to jewelry, photo frames, or keepsakes.

- Industrial Use: Create durable identification tags, serial numbers, or barcodes for equipment.

- Creative Projects: Bring custom designs to life for signage, artwork, or decor.

Why Partner With Us?

- Top-Notch Equipment: We use advanced laser engraving machines for optimal results.

- Expert Craftsmanship: Our experienced team ensures each project meets your exact specifications

- Quick Turnaround: We understand deadlines and prioritize timely delivery

- Affordable Pricing: High-quality service that fits your budget.

Laser Cutting Service

CNC Laser Cutting

Our Laser Cutting Service combines precision, efficiency, and versatility to bring your creative and industrial projects to life. Whether you need intricate designs for artistic projects or precise cuts for manufacturing, we deliver unparalleled results using advanced laser technology.

What We Offer:

Material Versatility: We work with a wide range of materials, including:Metals (stainless steel, aluminum, copper),Wood (plywood, MDF, hardwood) ,Plastics (acrylic, polycarbonate, ABS) ,Fabrics and leather.

Custom Designs: Share your ideas, and we’ll bring them to life with:Intricate engraving, Complex patterns, High-precision cuts

Applications:Signage and branding ,Prototyping and manufacturing Architectural models Gifts and personalized items Decorative art and more!

Why Choose Us?

- Cutting-Edge Technology: Our state-of-the-art laser machines ensure accuracy and smooth edges every time.

- Expert Team: Skilled technicians guide your project from concept to completion.

- Fast Turnaround: We value your time, ensuring your projects are delivered promptly.

- Eco-Friendly Practices: We minimize waste and prioritize sustainable materials where possible.

How It Works:

- Submit Your Design: Provide your design files in preferred formats (e.g., DXF, AI, SVG, PDF).

- Material Selection: Choose from our curated material library or provide your own.

- Quotation and Approval: Receive a transparent quote before starting.

- Production: Watch your vision come to life with laser precision.

- Delivery: Pick up your project or have it shipped directly to you.

Laser Cutting Design Service

Laser Design Service

Transform your creative ideas into reality with our professional Laser Cutting Design Service. We specialize in precise, high-quality laser cutting and engraving, tailored to meet the needs of artists, businesses, and hobbyists alike. Whether you’re working on intricate patterns, custom prototypes, or large-scale production, we’ve got you covered.

What We Offer:

Material Variety: We work with a wide range of materials, including wood, acrylic, metal, paper, fabric, and more.

Precision Cutting: Advanced laser technology ensures sharp, detailed cuts with smooth edges every time.

Engraving Services: Add logos, text, or intricate patterns to personalize your items.

Prototyping and Production: Whether it’s a single item or bulk production, we handle projects of any size.

Custom Designs: Upload your design or work with our experts to create bespoke laser-cut pieces.

Why Choose Us?

- Expertise: Our team has years of experience in design and laser cutting for a variety of industries

- Advanced Equipment: We use state-of-the-art laser cutters to deliver unparalleled precision and speed.

- Fast Turnaround: We work efficiently to meet tight deadlines without compromising quality.

- Eco-Friendly Practices: We focus on sustainability by optimizing material usage and recycling whenever possible.

- Affordable Pricing: Competitive rates with no hidden fees.

Applications:

- Decor and Signage: Create personalized home decor, business signage, or event displays.

- Prototypes and Models: Develop intricate prototypes for architecture, engineering, or design projects.

- Jewelry and Accessories: Design one-of-a-kind pieces with fine details.

- Corporate Branding: Engrave logos and promotional items for your business.

- Art and Crafts: Bring your artistic vision to life with precision and creativity.

How It Works:

- Submit Your Design: Send us your digital files (DXF, SVG, AI, or PDF) or let us help you create one.

- Material Selection: Choose from our wide range of available materials.

- Get a Quote: Receive an upfront, transparent quote for your project.

- Production: Watch your design come to life with our precision laser cutting technology.

- Pickup or Delivery: Collect your finished product or have it shipped directly to you.

Sheet Metal Bending Service

Laser Design Service

Our Sheet Metal Bending Service delivers precision and quality to meet your project requirements. With advanced equipment and expert craftsmanship, we provide custom bending solutions for various industries, including automotive, construction, aerospace, and manufacturing.

Why Choose Our Service?

High Precision: Utilizing state-of-the-art CNC press brakes, we ensure accurate and consistent bends for all types of sheet metal.

Material Versatility: We work with a wide range of metals, including steel, aluminum, stainless steel, and more.

Custom Solutions: From simple angles to complex geometries, our team can handle all your custom bending needs.

Quick Turnaround: We pride ourselves on delivering high-quality work with minimal lead times.

Capabilities

- Bending thicknesses from 0.5mm to 12mm.

- Lengths up to 3.2 meters.

- Precision tolerance up to ±0.1mm.

- Support for prototypes, small batch production, and high-volume orders.

- Applications Enclosures and casings.

- Architectural and decorative panels.

- Automotive panels and components.

- Brackets, frames, and structural elements.

How It Works

- Consultation: Share your design requirements, material specifications, and dimensions.

- Quoting: We provide a detailed quote tailored to your needs.

- Production: Our team processes your order with precision and care.

- Delivery: Your bent sheet metal parts are shipped or available for pickup promptly.

Sheet Metal Fabrication Works

Sheet Metal Fabrication

Sheet metal fabrication is the process of creating metal structures, components, and parts through various cutting, bending, and assembling techniques. This manufacturing method is widely used across industries such as automotive, construction, aerospace, and consumer goods.

Key Processes in Sheet Metal Fabrication

Cutting:

Techniques: Laser cutting, waterjet cutting, plasma cutting, shearing.

Purpose: To precisely cut the sheet metal into the desired shapes and sizes.

Bending: Techniques: Press brakes, roll bending, and folding machines. Purpose: To shape metal into curved or angled forms.

Welding: Types: TIG, MIG, spot welding, arc welding.

Purpose: To join metal pieces together.

Forming:Techniques: Stamping, rolling, punching, and deep drawing.

Purpose: To achieve complex geometries or features.

Assembly: Tools: Fasteners, rivets, adhesives.

Purpose: To combine multiple parts into a final product.

Finishing:Methods: Powder coating, galvanizing, polishing, anodizing. Purpose: To enhance durability, aesthetics, and corrosion resistance.

Common materials in sheet metal fabrication include:

- Steel (stainless, carbon, galvanized)

- Aluminum

- Brass

- Copper

- Titanium

Applications

- Construction: HVAC ducts, roofing, and structural components.

- Automotive: Body panels, engine components, and exhaust systems.

- Aerospace: Aircraft fuselages, wing panels, and support structures.

- Electronics: Enclosures, brackets, and heat sinks.

- Consumer Goods: Kitchen appliances, furniture, and decorative items.

Advantages of Sheet Metal Fabrication

- Versatility: Suitable for a wide range of industries.

- Durability: Provides strength and longevity.

- Customizability: Accommodates complex designs.

- Cost-effectiveness: Scalable for both small and large production runs.

Challenges

- Material Waste: Efficient planning is necessary to minimize scrap.

- High Initial Costs: Requires investment in specialized machinery.

- Precision Requirements: Skilled labor and advanced tools are essential for accuracy. Conclusion

- Conclusion:Sheet metal fabrication is a cornerstone of modern manufacturing, enabling the creation of robust and functional products. With advancements in technology, such as CNC machining and automation, the industry continues to evolve, offering improved precision, efficiency, and innovation.